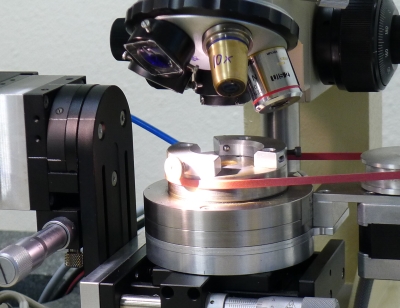

The universal laser drilling system for drawing dies is suitable for drilling natural and polycristalline diamond dies with drill diameters from 0.025 to 12 mm. In doing so, the machining of the entrance, the exit and the reduction cone as well as the bearing can be machined precisely. The maximum height of the diamond insert is not limited. The laser is also suitable for drawing die repairs wich minimizes long ultrasonic machining times.

To obtain the password for the product video, please fill in the contact form.

Specifications

- Diode end pumped Nd:YAG laser, high beam quality, fundamental mode resonator, Q-switched pulsed 1-Hz to 10-kHz,

optimized laser pulse length and pulse peak power to remove natural diamond, ultra stable laser resonator, recommended room temperature 18 to 25°C - Hard stone test plates for the laser resonator and for all positioning and adjustment superstructures

- Integrated laser power measurement

- Air-cushioned precision rotary table for the clamping of drawing dies between 25 and 30 mm; mount diameter with concentricity less than 1 µm

- Optional adapters for mount sizes 10 to 55 mm

- 3- axis precision tables with stepping motors and 1 µm resolution

- Precision rotary measuring table for angle measurement for double-sided angle drilling of front and back

- CCD- colour camera with measuring function

- External supply: 1.5 kW, 230 VAC, filtered compressed air 6 bar, water cooling between 18 and 22°C

Dimensions: (WxDxH) 190x80x120 cm weight: approx. 600 kg